When it comes to extending the lifespan of components and improving their performance in demanding industrial environments, hard chrome plating is one of the most reliable and widely used solutions. But what exactly is hard chrome plating, and why is it such a staple in engineering? In this article, we examine what hard chrome is, its advantages, and its crucial role in modern manufacturing.

What Is Hard Chrome Plating?

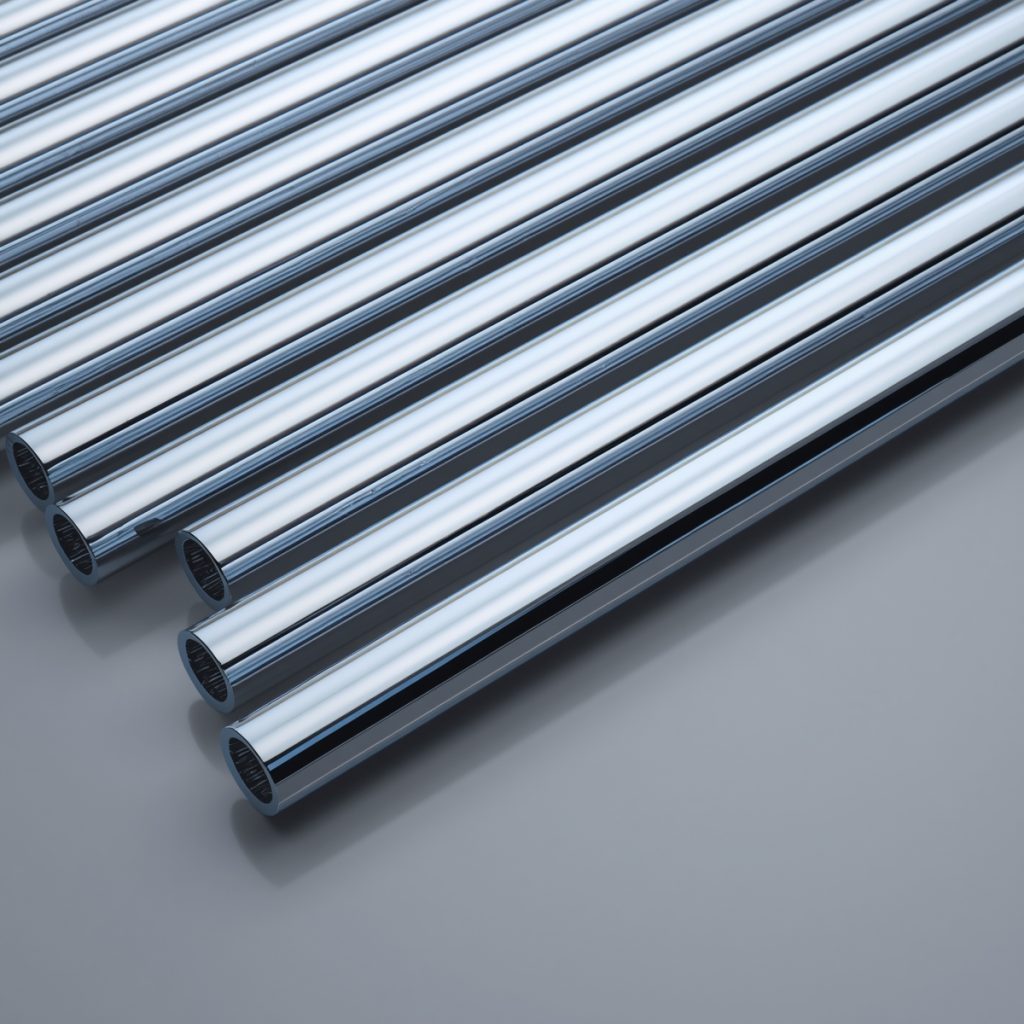

Hard chrome plating is also called industrial chrome plating, and it is a process which involves electroplating a layer of chromium onto a metal surface. Unlike decorative chrome, which is applied in thinner layers for aesthetic purposes, hard chrome is typically applied in much thicker layers (ranging from 10 to 500 microns) to enhance the functional properties of the component.

This process improves wear resistance, reduces friction, increases corrosion resistance, and restores the dimensions of worn parts — making it essential for parts that operate in high-stress or high-friction environments.

Why Is Hard Chrome Used in Engineering?

In engineering, components are often subjected to extreme conditions — whether it’s high pressure, heavy loads, or constant motion. Hard chrome plating provides a protective solution that enhances both the performance and longevity of parts, thereby reducing downtime and maintenance costs.

Superior hardness

With a hardness of up to 70 HRC, chrome-plated surfaces are highly resistant to abrasion.

One of the most defining benefits of hard chrome is its exceptional hardness. With a Rockwell hardness rating of up to 70 HRC, hard chrome significantly enhances a component’s ability to withstand abrasion, impact, and surface wear — particularly in high-load or high-cycle environments.

This makes it ideal for use in hydraulic cylinders, machine tools, and other components exposed to intense mechanical stress. The hardness of the chrome layer not only extends the lifespan of the part but also reduces the frequency of maintenance or replacement.

Corrosion protection

Chrome acts as a barrier against moisture, chemicals, and other corrosive agents.

Hard chrome plate provides an effective barrier against moisture, chemicals, and corrosive agents that commonly degrade uncoated metals. This is especially valuable in applications where components are exposed to harsh environments, such as marine, chemical processing, or mining industries.

The microcrack structure of hard chrome helps facilitate oil retention and resist chemical attack, thereby reducing the risk of oxidation or rust formation over time. Protecting vital parts from corrosion helps manufacturers avoid costly downtime and premature failures.

Reduced friction

This is critical for components that must move smoothly and efficiently.

Reduced friction is essential in systems where smooth, continuous motion is critical — such as piston rods, shafts, and sliding components. The naturally low coefficient of friction offered by hard chrome minimises metal-to-metal contact, thereby improving mechanical efficiency and reducing heat build-up and component wear.

This reduction in friction not only improves performance but also contributes to energy savings and extended service intervals.

Dimensional restoration

Worn or undersized parts can be brought back to precise tolerances, avoiding the need for costly replacements.

Over time, critical components such as shafts, rollers, or bearing surfaces may suffer wear or dimensional loss that renders them out of tolerance. Hard chrome plating services allow engineers to restore those surfaces to precise dimensions without needing to manufacture new parts from scratch.

After the plating process, components are precision-ground back to their original specifications, ensuring full functionality and compatibility. This makes hard chrome plating a cost-effective alternative to part replacement, particularly for legacy machinery or custom-fabricated components.

Common Applications in Engineering

Hard chrome plating is used across a broad range of engineering and manufacturing sectors. Typical applications include:

- Hydraulic cylinder rods

- Piston rods

- Pump shafts

- Printing rollers

- Automotive and aerospace components

- Moulds and dies for plastic injection

Whether it’s restoring an old part or increasing the resilience of a newly machined component, hard chrome is a go-to solution for many engineers and manufacturers.

The Role of Precision Grinding

Hard chrome plating doesn’t stand alone — it often goes hand-in-hand with precision grinding. After plating, components must typically be ground back to exact dimensions to ensure they meet tight tolerances and performance specifications.

At Davies Precision Grinding, our precision grinding capabilities make sure each component meets the required standards of accuracy and performance.

Why Choose Davies Precision Grinding for Hard Chrome Plating Services?

With decades of experience in the industry, Davies Precision Grinding are trusted chrome platers Birmingham businesses can rely on. We serve a wide range of manufacturing clients across the UK with our expert craftsmanship, fast turnaround times, and commitment to quality.

We provide:

- In-house chrome plating and grinding under one roof

- Tailored services for both individual components and batch runs

- Competitive pricing and responsive lead times

- Trusted chrome platers in Birmingham with a long-standing reputation

If you’re looking for reliable, high-performance chrome plating services, we’re here to help. Learn more about our hard chrome plating services or get in touch to discuss your requirements.